This highly-reliable super micro milling machine is suitable for chemical, medicine, food, feed, pesticides, non-me

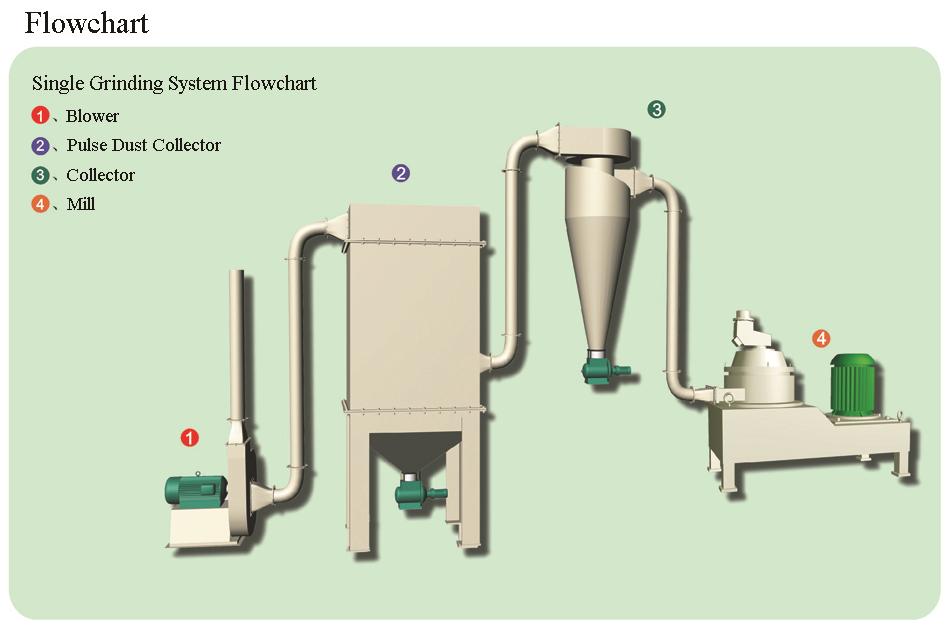

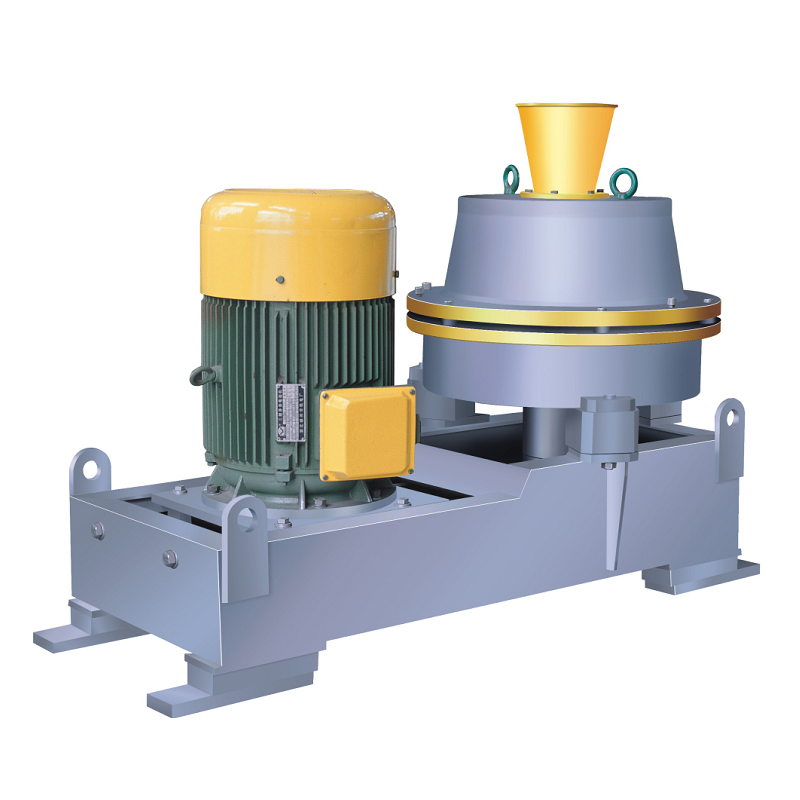

The material is fed into the top of top-housing and be scattered by the pre-comminution blades which are on the rotor. Then the material moves towards to the wall of stator and enter into the comminution chamber. A large number of air flow, which is generated from the high-rotated rotor, is affected by the inner fixed and moving parts and be guided to be countless rapids. The air rapids in the comminution chamber make the materials to speed up to the same speed level. And then, the speed and the rotation direction of the materials are changed in an instant. Then the materials particles bump into each other and becomes ideal fine powder. Only a little part of powder is impacted into fine powder because of the inner fixed and moving parts. The material in the chamber is circled by the air flow all the time and thus, the heat generated from the impaction is also been taken away by the air flow. According to the principle above makes the model HWV Turbo Mill suitable for both grinding and drying.

① Adopting the cone-shaped rotor and stator, can adjust the gap between of rotor and stator by rising and falling the up-housing (stator) to control the finished particle size and production. The adjustable gap range is 0~5mm.

② The rotor is made of special European imported high-strength, high-hardness and wear-resistant casting steel. The speed of rotor outer line can reach at least 125 m/s. And the service life is long.

③ The housing is computer aided, which make the smoother-discharge, lower-noise. Also when process the sticky and cohesive materials, it can reduce the wall-sticking to a great extent.

④ The air volume is very big when it runs, which could reduce the milling temperature. It is suitable for the thermoplastic and fibrous material. The particle size is evenly.

⑤ Can add the fan blade under the rotor to increase the air volume.

⑥ Easy maintainence, operation and cleaning.