SSFM Double Rotor Thermoplastic Mill is a new generation of plastic mill, which is designed and innovated by ourselves and combine the foreign advanced crushing technology. The raw material with the particle size of 610mm, be delivered to the high-speedly rotated milling cavity by the feeder and becomes the powder of 15~80 mesh. Because of the fast discharge, the troubles of stickness and low output of the heat-sensitive material are solved. The powder particle size, the size distribution and liquidity are adjustable by adjusting the gaps of the mill discs.

① First domestic dual power system, the output is 2 to 5 times higher than ordinary machines, be applicable to PP, PVC, PE, PS, PA, PC and other plastics.

② The unique machine level grinding disc adjustment device can quickly and easily adjust the gap of the grinding disc to achieve the fineness of the powder. Easy installation and maintenance by opening the machine door.

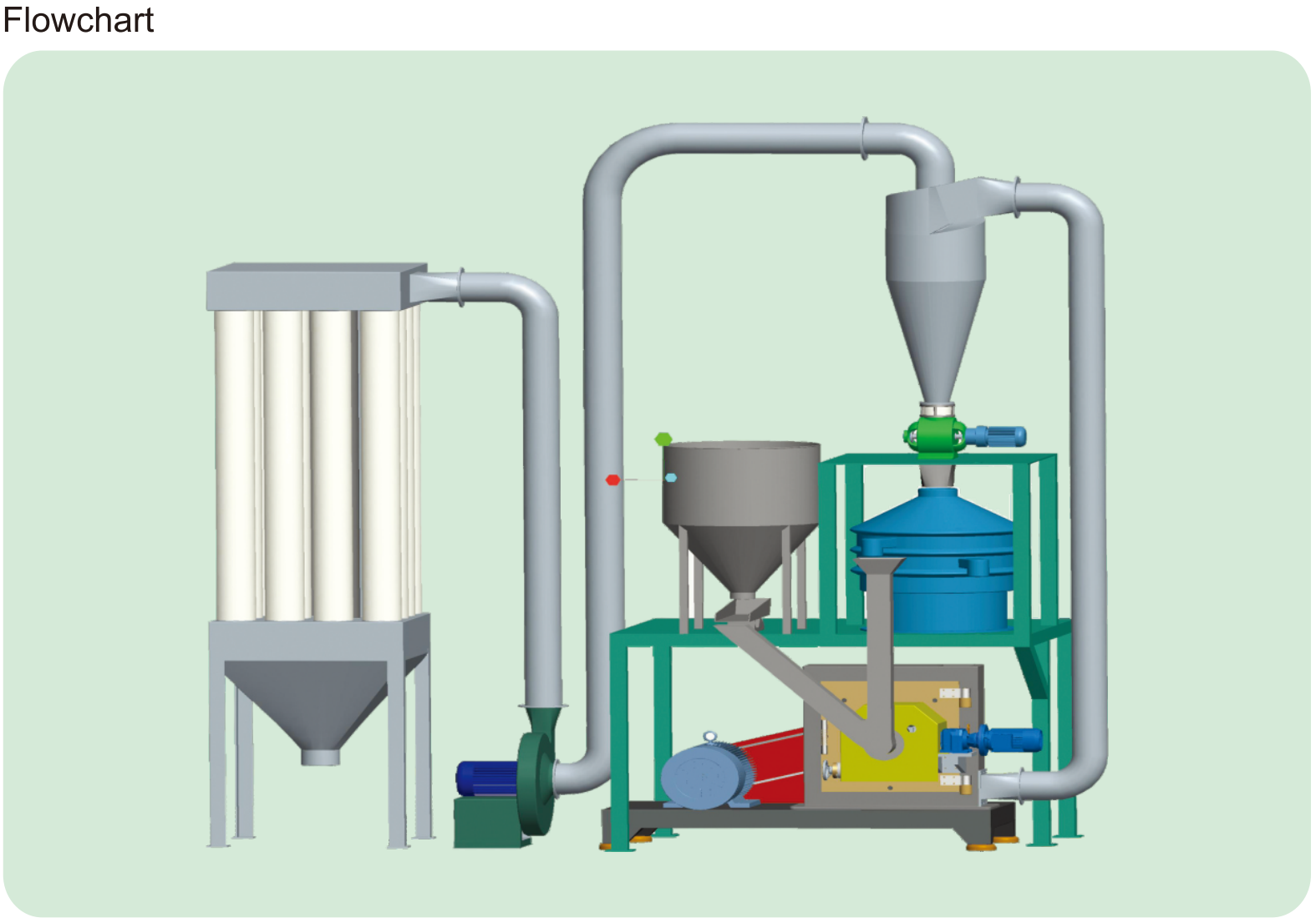

③ The whole set is equipped with water circulation cooling, vacuum feeding system, vibrating screen, rotary valve, etc.

④ The tool adopts advanced technology and special treatment, easy replacement and good wear resistance.