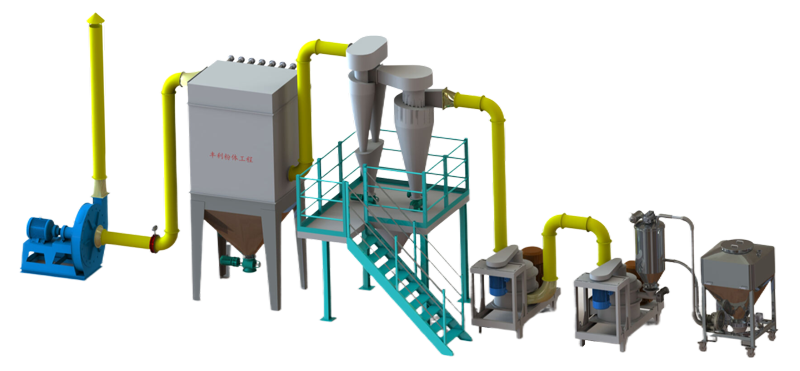

This machine is widely used in the chemical industry, dyes, paints, coatings, pesticides, pharmaceuticals, food, feed, me

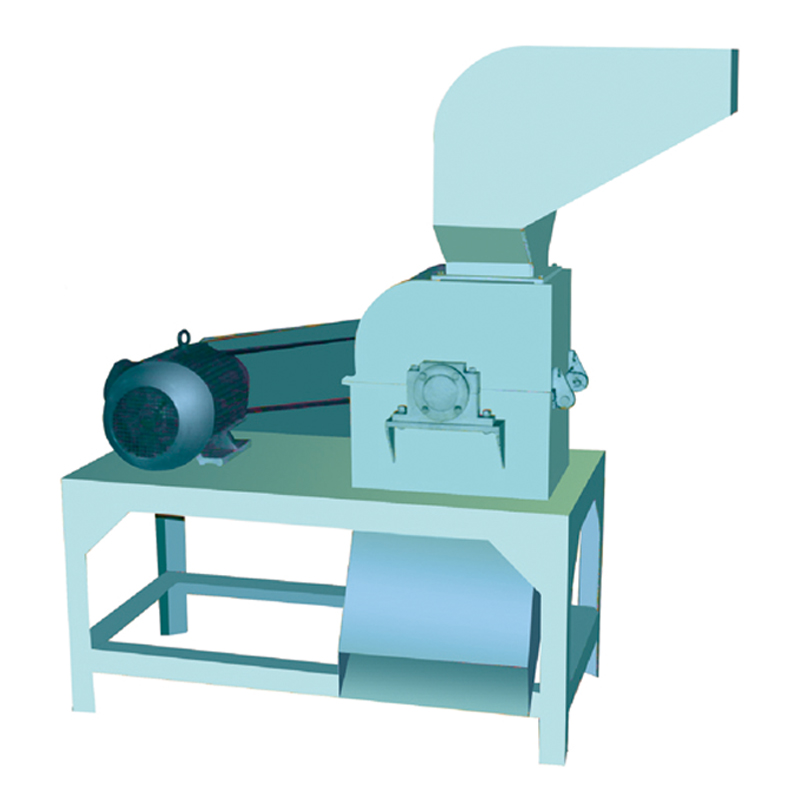

This machine mainly consists of hopper, the upper body, the lower body, rotor, hammer, screen, rack, discharge port and other components. Grinder work, the motor-driven spindle (rotor) (the uniform number of pieces of hammer around rotor) high-speed rotation. The compacting area of the hammer and stator is compact, allowing the material entering the machine to closely and strongly impact the hammer in the swirling air flow and grind again in the gap between the hammer and the stator. During this process, the rotor sucks in a lot of air and serves to cool the machine, the abrasive and deliver the fines. Material crushing fineness depends on the nature of the material and the size of the screen, as well as the material air throughput.

The machine has the characteristics of compact and reasonable structure, small size, low energy consumption, high efficiency, smooth transmission, low noise, reliable sealing, good self-cooling function, easy installation and maintenance, easy dismantlement, easy repair and easy replacement of wearing parts.